Cheap Forklift Tyres, Are they worth it?

They’re all the same aren’t they?

The initial purchase price of a tyre should represent value for money, and not just be the cheapest alternative, meaning your invoiced amount today should pay dividends for you tomorrow, and the next day, and the next day…

By investing a little more upfront, a quality 3 compound resilient tyre will:

- Reduce stresses & strains on the truck AND operator

- Be more fuel-efficient, as most will have a lower rolling resistance

- Make sure the lifting capacity of the truck is not compromised

- Last longer than a 2 compound tyre, meaning the cost per hour will actually be lower in the long run.

Not only on resilient tyres, but press on band tyres are also prone to cheap imitations which sound too good to be true when you look at the price tag, & quite often fail very shortly after being fitted.

Driving Performance

Did you know having the right tyres on your truck can facilitate an extra 14.16% output per shift? Furthermore, around 40% of consumers order the wrong compound or size of industrial tyres, so what are the real implications of them wrong?

Operating a forklift truck with the wrong tyres can unsafely reduce its lifting capacity and stability. As well as putting excess stress on major components, which in turn raises both maintenance and fuel costs, whilst lowering productivity. Furthermore, tyres have a great effect on operator comfort, which when negative can be a major de-motivator to your workforce. The graph below shows the difference in vibration when changing the tyre type, ground type and forklift type. Therefore choosing your right tyres will not only improve your trucks productivity but your workforce’s and lower your maintenance costs.

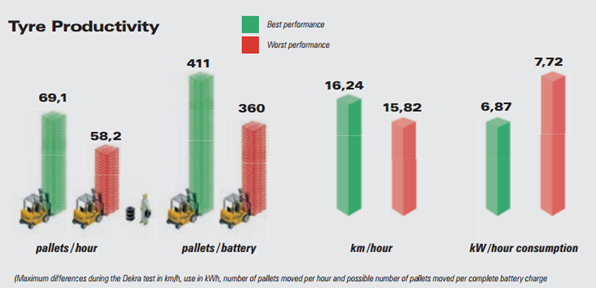

In addition to the factors mentioned prior, a change in tyre can result in a surprising change in productivity. The graph below shows the best and worst case of a 14 tyre study which used a single truck, driver and application in order to keep it consistent. The same type of tyre was also used, just the quality changed.

The test reveals an extra 10.9 pallets an hour can be shifted from best to worst case, resulting in an extra 51 pallets per battery charge, an extra 14.17% per shift. One of the key contributing factors could be a result of the extra speed which can be achieved through having the right high-quality tyre, with the trucks speed rising by just under half a mile an hour. Furthermore, noticeably the best performance tyre even consumes less energy, meaning that per battery charge the truck is even lasting longer. This suggests there will also be a fuel-saving when adapted to engine forklifts.

Tyre types and application:

Cushion tyres – A press on a tyre that is made with a metal band and a rubber attached to it. Used only on smooth pavements and warehouses with concrete flooring where space may be an issue as cushion tyres have a turning radius that is smaller than pneumatic tyres.

Solid tyres – The most common tyre. They are the same as pneumatic, however not filled with air therefore they don’t provide a cushioning effect. They do not puncture or go flat and are long-lasting. Excellent for indoor use or light outdoor use, but not for rough outdoor or uneven surfaces.

Pneumatic tyres – Similar to truck tyres, filled with air, thick, deep tread, strong wear-resistant rubber. They extend the running life of a forklift by providing a cushion effect between the forklift and the ground. For use on uneven and rough surfaces.

Polyurethane wheels – Generally used for indoor forklifts. They are normally pressed onto the wheel (easiest way to put on a tyre). They have an adequate level of traction for indoors and possess a ‘small rolling resistance’ that extends their running life. This tyre is generally found on indoor forklifts such as reach trucks and stackers.

Subscribe to our latest newsletter

Subscribe now to receive the latest offers, stock updates, exclusive product releases, and company news directly to your inbox.